How to Implement Manufacturing Automation Effectively?

Manufacturing automation is revolutionizing production processes worldwide. Renowned expert Dr. James Holloway states, “Effective implementation is key to realizing automation's benefits.” His insight emphasizes the importance of a strategic approach.

In an era where speed and efficiency matter, manufacturing automation offers compelling advantages. However, many companies struggle to implement these systems effectively. Issues often arise from misunderstandings and inadequate planning. A lack of clarity can lead to costly mistakes that hinder progress.

Attention to detail is crucial. Understanding the specific needs of a production line can make a significant difference. Automation should not be a one-size-fits-all solution. Each industry has unique challenges that demand tailored strategies. Reflecting on the journey of adopting manufacturing automation can reveal gaps in knowledge and execution, pushing organizations to adapt and improve.

Understanding Manufacturing Automation: Key Concepts and Benefits

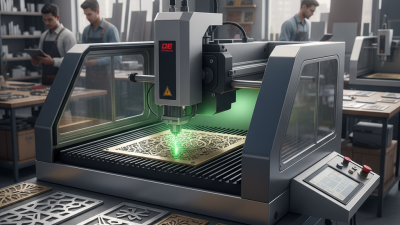

Manufacturing automation is transforming how industries operate. Understanding its key concepts can help businesses harness its benefits. Automation involves using technology to perform tasks with minimal human intervention. This can include robotics, software, and machine learning.

The benefits are significant: increased efficiency, better quality control, and cost savings. Automation reduces repetitive tasks. Employees can focus on higher-value work. However, companies must also consider potential downsides. There may be resistance to change from staff. Training is essential to ensure everyone is on board. This could be a lengthy process.

Additionally, automation can lead to job displacement. While it creates new roles, some employees may feel vulnerable. It's crucial to communicate openly about these changes. Businesses should also reflect on their automation goals. An overemphasis on technology can lead to overlooking human skills. Balancing automation with a skilled workforce is vital for success.

Manufacturing Automation: Key Benefits Over Time

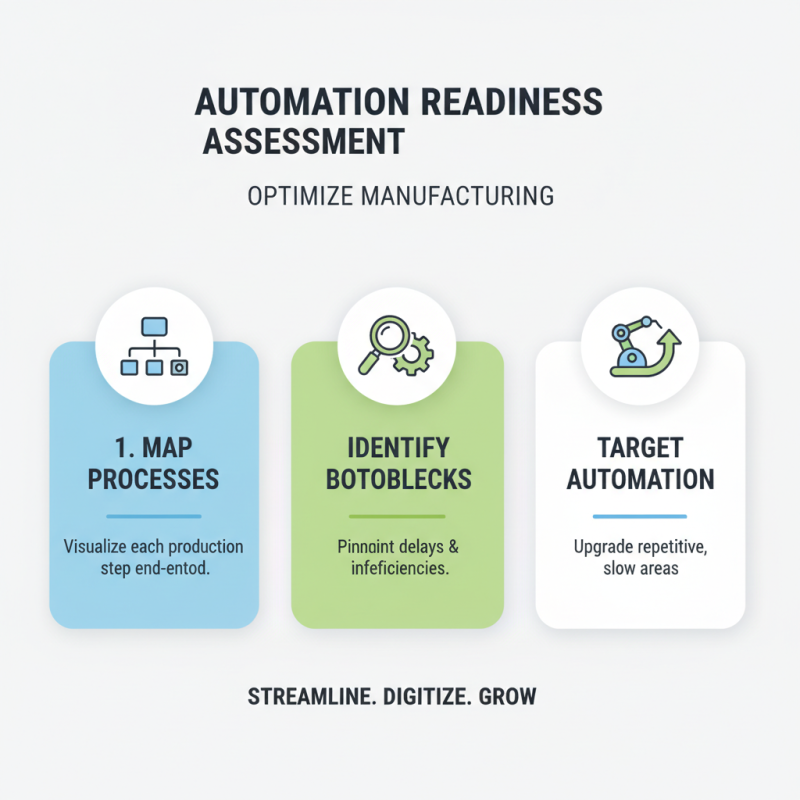

Assessing Current Manufacturing Processes for Automation Opportunities

Assessing current manufacturing processes is crucial before embracing automation. Start by mapping out each step in your production lines. This visual representation helps identify bottlenecks. Take note of processes taking too long or causing consistent delays. These areas are ripe for automation.

Next, engage with your team. Gather feedback on pain points and inefficiencies they face. Employees often know best where the problems lie. Use their insights to prioritize which processes to automate first. Don't overlook smaller tasks. Automating simple, repetitive actions can lead to significant time savings.

Monitor data closely. Look for patterns in production performance. Sometimes, automation solutions can create new challenges. Keep an eye on how changes affect team dynamics. Not all automated processes yield the expected benefits. Adjustments may be required. Embrace flexibility as you refine your approach.

Selecting the Right Technologies and Tools for Automation Implementation

Selecting the right technologies and tools for manufacturing automation is crucial. Many companies struggle with this step. It can lead to failures and wasted investments. It is essential to evaluate your specific needs. Consider the scale of production. What processes can benefit most from automation?

Look for technologies that fit your industry. Robotics are popular for repetitive tasks. They increase efficiency but can be costly. Software solutions support data analysis and production monitoring. Choose tools that integrate well with current systems. This helps in streamlining operations.

Tips for selection:

- Assess your budget. Avoid overspending early on.

- Start small. Test new technologies before full implementation.

- Get feedback from your team. They know the processes best.

Keep in mind that not every technology is perfect. Some may not deliver as expected. Continuous assessment is key. Watch for changes in productivity. Adjust your approach as needed. Stay open to new solutions.

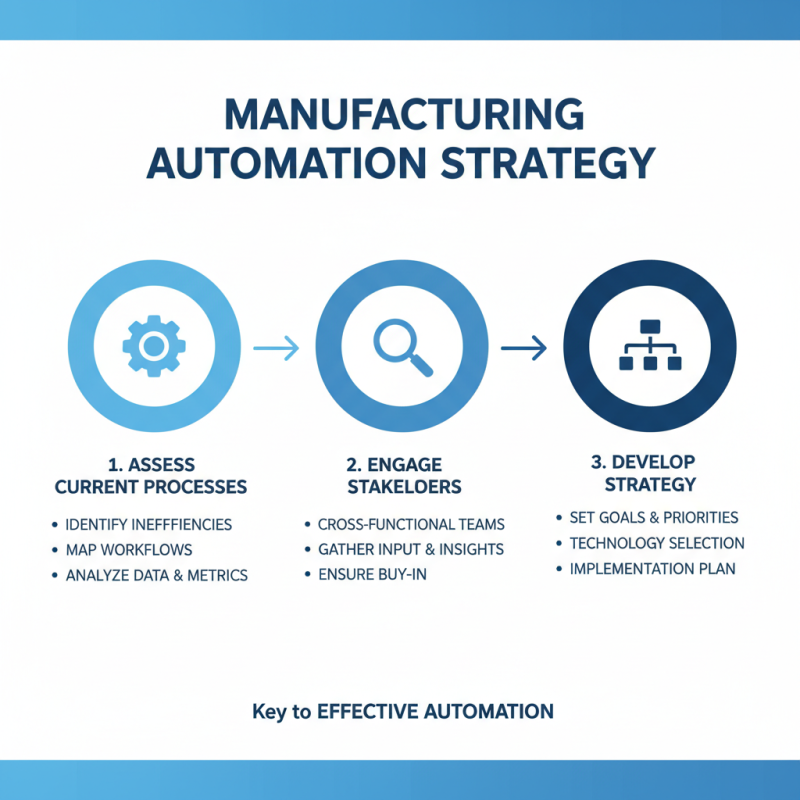

Developing a Comprehensive Automation Strategy and Roadmap

Developing a comprehensive automation strategy is crucial for effective manufacturing automation. Start by assessing your current processes. Identify inefficiencies and areas requiring improvement. This assessment must involve all stakeholders. Every department has unique insights. Their input will ensure a well-rounded approach.

Tips: Involve your team early. Gather their feedback on current issues. This will help build consensus and commitment.

After identifying key areas, prioritize them based on impact and feasibility. Some projects may require more resources. Often, what seems simple may be challenging to implement. Be realistic about your timeline. Automation doesn’t happen overnight.

Tips: Set small milestones. Celebrate achievements along the way. This keeps the team motivated.

Develop a clear roadmap that outlines each step of the automation implementation. Include training sessions for staff. Change can be daunting, especially for those accustomed to traditional methods. Addressing concerns and providing support will ease the transition.

Reflection is essential during this process. Regularly evaluate the effectiveness of automation. Be open to making adjustments. What works initially may not work later. Embrace flexibility in your strategy. This adaptability will lead to long-term success.

Training Workforce and Managing Change for Successful Automation Integration

Training the workforce is essential for successful automation integration. Studies show that companies investing in employee training increase productivity by up to 30%. The shift to automation may cause anxiety among workers. Addressing their concerns should be a priority. A transparent approach helps build trust and reduce resistance.

Workshops and hands-on training sessions can boost confidence. Engaging employees early in the process fosters a sense of ownership. It’s not just about machines; it’s about people. According to research, a smooth transition hinges on effective change management. Companies report that organizations with structured change plans see 50% fewer delays in automation projects.

Regular feedback and open communication channels promote a collaborative environment. Encouraging employees to share their insights can lead to innovative solutions. However, not all attempts at automation yield positive results. Continued assessments are crucial to avoid unnecessary costs and disruptions. A culture of adaptability allows companies to refine strategies continually.

How to Implement Manufacturing Automation Effectively? - Training Workforce and Managing Change for Successful Automation Integration

| Dimension | Details | Importance Level | Implementation Status |

|---|---|---|---|

| Training Needs Assessment | Identify skills gaps in the workforce related to automation technologies. | High | In Progress |

| Skill Development Programs | Develop structured training programs to upskill employees on new technologies. | High | Not Started |

| Change Management Strategies | Implement strategies to manage resistance and gain buy-in from staff. | Medium | In Progress |

| Feedback Mechanisms | Establish channels for ongoing feedback from employees regarding automation processes. | Medium | Planned |

| Performance Metrics | Define key performance indicators to measure success of automation implementation. | High | Ongoing |

Arsun Engineers is the well-known manufacturer, exporter, and supplier of highly operational machines.

Products

Automation

Get in Touch !

- 56/1 Vithalwadi GIDC, 364001 Bhavnagar, Gujarat, India

- +91 9426 816 961

- +91 7222 841 841

- sale@wallandmachinery.com