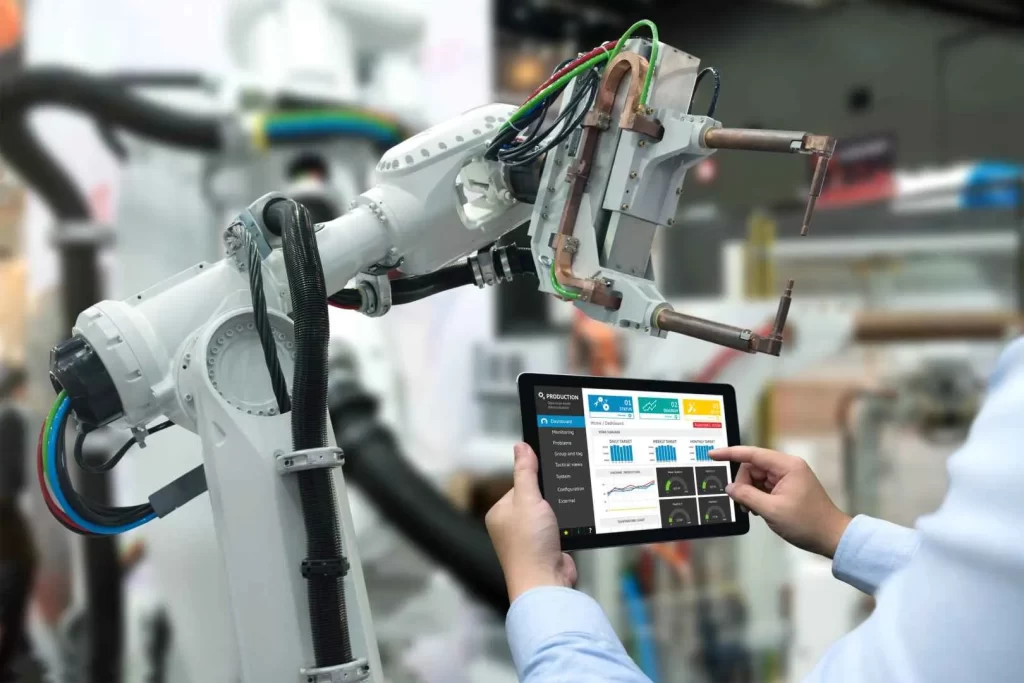

Digital Twin With IIOT

What is Digital Twin?

A Digital Twin is a virtual replica or simulation of a physical product, process, or system that mirrors its real-world counterpart throughout its lifecycle. This dynamic model is built on data-driven insights, enabling real-time monitoring, analysis, and optimization. By bridging the physical and digital worlds, a Digital Twin empowers businesses to enhance decision-making, minimize downtime, and maximize operational efficiency.

Why Digital Twin?

Real-Time Monitoring

Track the performance, condition, and behavior of your assets or processes with real-time data, enabling swift action and informed decision-making.

Process Optimization

Simulate and optimize processes to uncover inefficiencies, test various scenarios, and implement strategies that boost productivity and reduce costs.

Predictive Insights

Harness historical and real-time data to predict issues before they occur, enabling proactive measures that reduce downtime and maintenance costs.

Improved Decision-Making

Leverage actionable insights from the Digital Twin to make data-driven decisions that align with your operational goals.

How We Help

Customized Digital Twin Solutions

We develop Digital Twin models uniquely tailored to your operational needs, ensuring seamless alignment with your assets, processes, and business objectives.

Simulation and Testing

Our experts help you simulate real-world scenarios within the Digital Twin environment, enabling predictive analysis and operational improvements without disrupting live systems.

Integration and Deployment

We ensure smooth integration of your Digital Twin with existing systems and provide end-to-end support for a hassle-free deployment experience.

Ongoing Support and Optimization

Our services include regular updates, training, and maintenance to keep your Digital Twin accurate, effective, and aligned with your evolving needs..

Additional Services

Simulation and Virtual Validation

Before deploying robots to the production floor, we simulate their operations using tools like ABB Robot Studio, Kuka SIM Pro, and Fanuc Roboguide. This virtual validation ensures flawless execution, reduces deployment risks, and identifies optimization opportunities early in the process.

Retrofitting and Reprogramming

We can retrofit older robots or reprogram existing setups to meet new production requirements, extending the life and versatility of your robotic systems.

Multi-Brand Expertise

From ABB and Fanuc to Kuka and Yaskawa, we offer programming services across a wide range of robot brands, ensuring you receive expert solutions regardless of your hardware.

Collaborative Robots (Cobots)

Our services also extend to collaborative robots, helping you integrate and program these advanced systems to work safely alongside your workforce, enhancing flexibility and efficiency.

Applications of Digital Twin

Digital Twin technology has transformative applications across various industries, including :

Asset Performance Management

Monitor and analyze asset performance to ensure optimal efficiency and identify maintenance needs before failures occur.

Predictive Maintenance

Simulate asset behavior to predict issues, reduce unplanned downtime, and extend equipment lifespan.

Production Process Optimization

Optimize manufacturing processes by simulating workflows, testing new configurations, and identifying bottlenecks.

Supply Chain Simulation

Model and simulate supply chain operations to improve logistics, reduce costs, and enhance efficiency.

Energy Management

Track and optimize energy consumption in real time, reducing costs and supporting sustainability goals.

Quality Assurance

Use real-time data to ensure consistent product quality and implement process improvements.

Benefits of Digital Twin

Cost Savings

Reduced downtime, optimized operations, and predictive maintenance contribute to lower operational costs.

Enhanced Productivity

Streamline workflows and identify inefficiencies with advanced simulations.

Scalability

Flexible models that adapt to evolving processes and business needs.

Better Decision-Making

Comprehensive insights lead to more informed and confident decisions.

Why Choose Digital Twin?

Tailored Solutions

very Digital Twin is customized to fit your business requirements.

Technical Expertise

Our team combines industry knowledge with cutting-edge tools to deliver exceptional results.

End-to-End Support

From strategy to deployment and ongoing optimization, we ensure a smooth Digital Twin journey.

Commitment to Excellence

We focus on delivering value through innovative solutions that drive measurable outcomes.

Let's Bring Change Together

Explore how Digital Twin technology can revolutionize your operations.

Get in touch with us to start your journey toward smarter, more efficient processes.