Why You Should Consider a Wood Engraving Machine for Your Projects?

When it comes to creative projects, a wood engraving machine can be an invaluable tool. John Smith, a renowned expert in laser engraving, highlights, "A wood engraving machine can transform your ideas into tangible art." This statement reflects how such machines bridge the gap between imagination and reality.

The versatility of a wood engraving machine is astounding. You can create intricate designs, personalized gifts, and functional pieces. Imagine engraving a family name on a beautiful wooden plaque; it adds a personal touch. These machines are not just for professionals. Hobbyists can also benefit from their precision and ease of use.

However, the journey with a wood engraving machine can be challenging. Beginners may struggle with settings and material choices. It's crucial to embrace these learning moments as part of the creative process. Mistakes can lead to beautiful discoveries. Each project teaches something new and pushes craft skills forward.

Benefits of Using a Wood Engraving Machine in Creative Projects

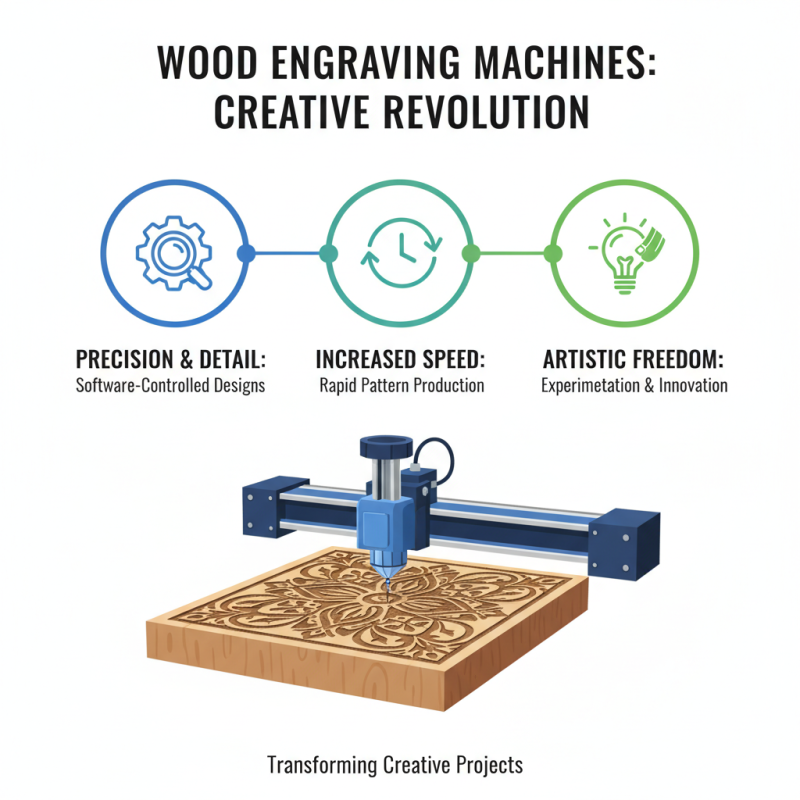

Wood engraving machines are changing the way we approach creative projects. They offer precision that manual methods cannot match. With software-controlled designs, you can produce intricate patterns quickly. This speed allows artists to experiment more freely, trying out various ideas without spending hours on each piece.

Creating beautiful engravings becomes more accessible. Beginners can find great joy in learning the craft. However, mastering the machine takes practice and patience. It’s not foolproof; mistakes happen. Sometimes, the machine may not engrave the way you envisioned. This calls for reflection and adjustment of your techniques.

The tactile nature of wood adds depth to your creations. Each grain pattern influences the final outcome. It's a unique challenge that can be early frustrating but ultimately rewarding. Embracing these imperfections can lead to unexpected beauty in your projects. Each piece becomes a reflection of not just your design but also your journey as a creator.

Types of Wood Engraving Machines and Their Features

When considering wood engraving machines, understanding their types and features is essential. Laser engraving machines dominate the market, often favored for their precision. They use focused beams of light to etch designs into wood. This technology can create intricate patterns and designs with minimal material waste. According to industry reports, the laser engraving market is expected to grow by 6% annually.

CNC routers are another popular option. These machines utilize computer numerical control for detailed cuts and engravings. They can handle larger pieces of wood and offer versatility for projects. CNC machines are particularly useful for three-dimensional engravings, which can add unique dimensions to your work. Industry insights indicate that CNC machines are becoming increasingly affordable, allowing hobbyists to invest in high-quality tools.

Tips: Consider the size of your projects. Choose a machine that fits your workspace. Look for features like adjustable speed and depth for better customization. Beginners might find simpler machines more manageable, but investing in advanced options could pay off in the long run. Reflect on your goals; a more expensive machine may offer capabilities you won’t initially use.

Key Considerations When Choosing a Wood Engraving Machine

Choosing a wood engraving machine requires careful thought. It’s not just about picking any machine. You need to consider the features that suit your projects. Think about the size of the engraving area. A larger space allows for bigger pieces but can also take up more room. The power of the engraver is crucial too. More power means deeper cuts but may also require more experience to handle.

Material compatibility is essential. Some machines work better with certain types of wood. Test how different wood types respond to engraving. It's vital to understand what works best for your desired outcome. Don’t overlook the software as well. User-friendly software can make a huge difference in the design process. If the software is too complex, it might discourage creativity.

Budget is another thing to reflect on. A high price tag doesn’t always guarantee quality. You may find good options that don't break the bank. However, cheaper machines might lack features or durability. It’s a balancing act of cost and quality. Research and reviews can guide your decision but remember that personal testing is invaluable. Nothing beats hands-on experience.

Why You Should Consider a Wood Engraving Machine for Your Projects? - Key Considerations When Choosing a Wood Engraving Machine

| Feature | Description | Considerations |

|---|---|---|

| Laser vs. CNC | Laser engravers use concentrated light to etch designs, while CNC machines use cutting tools for carving. | Consider the complexity of your designs and the materials you plan to use. |

| Engraving Area | The maximum size of the material that can be engraved. | Determine the size of your projects to choose a suitable machine. |

| Material Compatibility | Different machines support various materials such as wood, acrylic, leather, etc. | Ensure the machine can handle the specific materials you intend to use. |

| User Interface | The ease of use of the software and controls. | Look for intuitive interfaces, especially if you're a beginner. |

| Speed and Power | Refers to how quickly a machine can complete an engraving. | Consider the trade-off between speed and precision based on your needs. |

| Price Range | The cost of the engraving machine can vary significantly. | Set a budget that aligns with your project goals and frequency of use. |

| Maintenance | Regular upkeep required for optimal performance. | Look into the maintenance requirements to avoid downtime. |

Applications of Wood Engraving in Various Industries

Wood engraving has diverse applications across various industries. In the furniture sector, intricate designs can transform simple items into unique pieces. Personalized engravings add a special touch to tables and chairs, enhancing their appeal. This method allows artisans to create custom designs that reflect individual tastes.

In the gift industry, wood engraving offers endless possibilities. Customized wooden keepsakes make memorable gifts. Whether for weddings or birthdays, engraved items hold sentimental value. These pieces often tell a story, capturing moments that words cannot express. Many companies also use wood engraving for branding, making their products stand out.

The craft sector benefits greatly from wood engraving as well. Crafters can create art pieces that showcase their skills. However, they must be mindful of precision; errors can be costly. Learning the techniques takes time and practice, leading to improved outcomes. Even with state-of-the-art machines, craftsmanship plays a vital role in creating lasting impressions.

Maintenance Tips for Prolonging the Life of Your Engraving Machine

When you invest in a wood engraving machine, maintaining it is crucial for longevity. Regular cleaning keeps the device in top shape. Dust and debris can accumulate, leading to malfunctions. Use a soft brush or cloth to remove particles from the engraving area. Don't skip this step; small issues can become big problems over time.

Another consideration is lubrication. Many machines require regular oiling of moving parts to prevent wear. Follow the manufacturer’s guidelines. Over-oiling can attract dust, so be careful with application. A schedule for checks can help you stay on top of this; it’s easy to forget until something goes wrong.

Lastly, monitor your engraving bits. Replace them as needed. Dull bits can damage both the machine and your work. Engraving should be precise; a sharp tool is key. Learning to troubleshoot basic issues is also helpful. Sometimes, the smallest oversight can lead to significant setbacks. Reflect on your maintenance routine to ensure consistent performance.

Wood Engraving Machine Maintenance Analysis

Arsun Engineers is the well-known manufacturer, exporter, and supplier of highly operational machines.

Products

Automation

Get in Touch !

- 56/1 Vithalwadi GIDC, 364001 Bhavnagar, Gujarat, India

- +91 9426 816 961

- +91 7222 841 841

- sale@wallandmachinery.com