How to Choose the Right CNC Machines for Your Business Needs?

In today's manufacturing landscape, selecting the right CNC machines is crucial for success. The CNC market was valued at approximately $76.87 billion in 2020 and is expected to grow significantly. Experts predict a compound annual growth rate (CAGR) of around 6.7% during the next several years. This growth reflects the increasing demand for advanced machining technologies.

Renowned CNC expert Dr. Emily Carter emphasizes, “Choosing the right CNC machine is not just about cost; it’s about aligning technology with your specific business needs." With numerous options available, from milling machines to lathes, businesses must consider their unique production requirements. It is important to assess factors like material types, production volume, and precision needed.

Many new businesses often overlook these essential aspects. They may hastily purchase machines that do not fit their workflow. This leads to wasted resources and inefficiency. Therefore, careful evaluation and expert consultation are vital steps. Investing time in this process can yield long-term benefits.

Understanding Your Business Requirements for CNC Machines

When selecting CNC machines, it's crucial to understand your specific business requirements. Different industries have varying needs. For example, a woodshop will demand different features than a metal fabrication facility. Consider the materials you work with and the complexity of the designs you produce. This understanding can guide your machine choice significantly.

Think about production volume as well. Are you operating on a large scale or handling smaller, custom jobs? A high production capacity might require a more advanced machine with automation features. However, a smaller operation may function well with a simpler, manual CNC setup. Reflect on your current workflow and future goals. Sometimes, we rush into decisions, focusing solely on immediate gains. We must also evaluate long-term efficiency and potential growth.

Budget is another critical factor. Quality CNC machines can be expensive. Balancing cost with functionality can feel daunting. It often leads to overspending or purchasing underperforming models. Before rushing into a purchase, take time to assess what features are essential. Weigh the pros and cons carefully. Make sure the machine you choose aligns with your actual needs, not just trendy functions. This approach will save you time and resources in the long run.

How to Choose the Right CNC Machines for Your Business Needs?

| Machine Type | Ideal Material | Key Features | Typical Applications | Price Range (USD) |

|---|---|---|---|---|

| CNC Milling Machine | Metal, Plastic | High precision, multi-axis | Parts manufacturing, prototyping | $10,000 - $100,000 |

| CNC Laser Cutter | Wood, Acrylic, Metal | High-speed cutting, engraved designs | Sign making, custom designs | $5,000 - $150,000 |

| CNC Router | Wood, Composites | Versatile cutting, 3D carving | Furniture, cabinetry, artistic designs | $3,000 - $60,000 |

| CNC Plasma Cutter | Metal | High precision, quick cutting speed | Sheet metal fabrication, automotive parts | $12,000 - $80,000 |

| CNC Lathe | Metal | Precision machining, turning operations | Shafts, cylindrical parts | $15,000 - $100,000 |

Types of CNC Machines and Their Applications in Various Industries

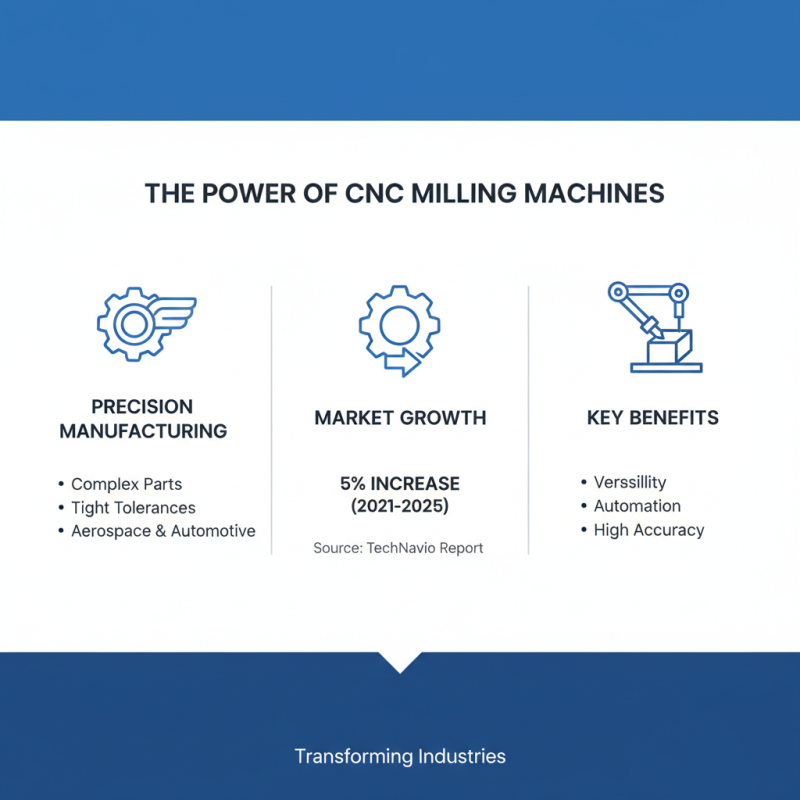

In various industries, CNC machines play a critical role. Each type serves different applications. For instance, CNC milling machines excel in producing complex parts. They can achieve precise cuts and shapes, making them ideal for aerospace and automotive sectors. According to a report from TechNavio, the global CNC milling machine market is expected to grow by 5% from 2021 to 2025.

CNC lathes are popular for their ability to create cylindrical parts efficiently. They are widely used in the manufacturing of medical devices and components. This segment is projected to expand significantly, driven by innovations in design and materials. However, businesses often overlook the importance of proper training for operators. Without adequate skills, even the best machines can underperform.

Laser cutting machines, another type, specialize in high-speed and quality cutting. They are key in industries like electronics and sheet metal fabrication. Yet, the initial setup and maintenance costs can deter potential adopters. A well-researched strategy is essential to justify these investments. Enhanced capabilities can lead to higher productivity and profitability in the long run.

Evaluating Key Features and Specifications of CNC Machines

When choosing the right CNC machines, understanding the key features and specifications is crucial. Consider accuracy and precision. Look for machines that offer high-resolution capabilities. Your production quality depends on it. A machine that can achieve is a must for intricate designs. Pay attention to the types of materials it can handle. Some machines struggle with harder materials, limiting your options.

Another important aspect is the machine's size and design. Ensure it fits efficiently in your workspace. Bigger isn’t always better. Often, smaller machines can perform just as well. Evaluate the ease of use. Look for user-friendly interfaces that can save training time. Complex controls can lead to frustration and wasted hours.

Tips: Always request a demo. Testing the machine is essential to gauge its performance. Think about after-sales support. A good warranty can save you in the long run. Don’t overlook power consumption. An efficient machine lowers operational costs. Remember, not every feature adds value. Focus on what aligns with your business needs.

Budget Considerations and Cost Analysis for CNC Investments

When investing in CNC machines, budget considerations are crucial. A survey by CIMdata revealed that companies allocate an average of 30% of their total equipment budget to CNC technologies. This significant investment demands a thorough analysis of operational costs and long-term return on investment. The initial purchase price is only the beginning. Maintenance, software updates, and training add layers of financial commitment.

Considering depreciation is essential as well. CNC machines lose value over time, typically around 10-15% annually. This decline impacts resale value and can influence the overall budget. A detailed cost analysis should also assess energy consumption since modern machines are more efficient yet can still incur substantial operational costs. A 2021 report stated that energy expenses for CNC operations could represent up to 25% of manufacturing costs.

Investing in CNC machines without thorough planning can lead to financial strain. Missteps like over-specifying features or underestimating maintenance needs can be costly. Not considering the lifecycle of the machines may affect profitability. Therefore, businesses must reflect on their specific needs and analyze all associated costs. Choosing the right CNC technology is an opportunity to maximize efficiency while managing financial risks effectively.

Choosing Between New vs. Used CNC Machines for Your Needs

Choosing between new and used CNC machines is a critical decision for your business. New machines often come with the latest technology and warranties. They are more reliable but can be quite expensive. Investing in a new machine means enjoying advanced features that improve efficiency and precision. However, you may face longer lead times and higher upfront costs.

On the other hand, used CNC machines offer a budget-friendly alternative. You can find well-maintained options that still deliver good performance. However, there is often less information available about their history. You might encounter wear and tear, and repairs could be needed sooner than expected. Thorough inspections are essential to ensure functionality.

Consider your specific needs carefully. Think about production volume and the types of materials you will work with. If your business requires versatility, a new machine may be wise. Yet, if your workload is manageable, a used machine could suffice. Make a list of pros and cons to guide your choice. Reflect on the long-term implications of each option before deciding.

Comparison of New vs. Used CNC Machines

Related Posts

-

Top 5 Benefits of Using a Metal Engraving Machine in Your Business?

-

Why You Should Consider a Wood Engraving Machine for Your Projects?

-

Top 10 Best CNC Engraving Techniques for Precision and Quality

-

2026 How to Choose the Best Industrial Automation Solutions for Your Business?

-

Top 10 Automation Solutions Tips to Boost Your Business Efficiency

-

How to Implement Manufacturing Automation Effectively?

Arsun Engineers is the well-known manufacturer, exporter, and supplier of highly operational machines.

Products

Automation

Get in Touch !

- 56/1 Vithalwadi GIDC, 364001 Bhavnagar, Gujarat, India

- +91 9426 816 961

- +91 7222 841 841

- sale@wallandmachinery.com