2026 How to Choose the Best Industrial Automation Solutions for Your Business?

In today's fast-paced industrial landscape, selecting the right industrial automation solutions is crucial. According to a recent report by MarketsandMarkets, the global industrial automation market is projected to reach $300 billion by 2026. Efficient automation can enhance productivity and reduce operational costs. However, the wide array of options can be overwhelming for businesses.

James Smith, an expert in industrial automation, states, "Choosing the right automation solutions requires a clear understanding of your business needs." This underscores the importance of assessing specific goals. Many companies face challenges in aligning automation technology with their operational strategies. They often invest in solutions that do not fully meet their requirements.

Understanding the unique features of industrial automation solutions is vital. It's not just about technology; it's about enhancing efficiency and scalability. A thoughtful approach is necessary when evaluating vendors. Companies need to be cautious and avoid common pitfalls. Proper research and evaluation of potential solutions can ensure a successful implementation for long-term benefits.

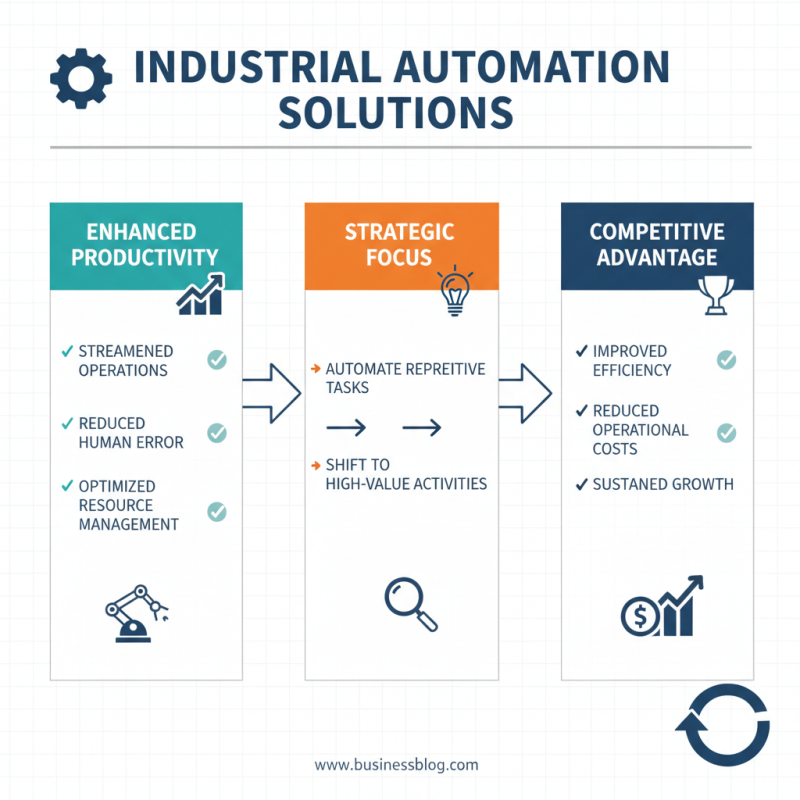

Understanding the Key Benefits of Industrial Automation Solutions

Industrial automation solutions offer significant advantages for businesses seeking to enhance productivity. These solutions streamline operations, reduce human error, and optimize resource management. By automating repetitive tasks, companies can focus on more strategic activities. This shift can lead to improved efficiency and reduced operational costs, which is crucial for maintaining competitiveness.

However, implementing automation isn't without challenges. Some businesses grapple with the initial investment and integration into existing systems. Employees may also resist change, fearing job loss or skill redundancy. It's vital to address these concerns through training and transparent communication. A well-thought-out implementation plan can ease this transition, fostering a positive environment for both staff and technology.

Additionally, industries must recognize that automation isn't a one-size-fits-all solution. What works for one business may not suit another. Customization is key. Continuous evaluation and feedback are essential to ensure that automation solutions meet evolving business needs. This ongoing process may reveal areas for improvement, sparking innovation and development within the company.

Identifying Your Business Needs for Automation Technologies

Identifying your business needs is crucial when considering industrial automation solutions. Start by assessing your current operations. Which processes consume the most time and resources? Data shows that automating repetitive tasks can increase efficiency by up to 30%. This suggests a significant potential for savings.

Look for pain points in your production line. Are there delays? Inefficient manual processes? The Manufacturing Institute reported that 84% of manufacturers face challenges with workforce skills and availability. Understanding these issues is key to selecting the right technology.

Tips: Engage your team in discussions about automation. Their insights might reveal overlooked inefficiencies. Consider conducting a pilot test of automation technologies. This can help you gauge effectiveness without a large upfront investment.

Finally, reevaluate your goals regularly. Technology evolves quickly. What works today may not be suitable in a few years. Reflect on your experiences to adapt your automation strategy as needed.

Evaluating Different Types of Industrial Automation Solutions Available

When exploring industrial automation solutions, it's essential to evaluate the types available. Options range from basic equipment to advanced systems. Some solutions include robotics, sensors, and software that streamline processes. Each type has its benefits and drawbacks, requiring careful consideration.

Basic automation can improve efficiency but may lack flexibility. It involves simpler machinery that can handle repetitive tasks effectively. Advanced solutions, like fully integrated systems, offer greater complexity. They can adapt to changes but often come with higher costs. Businesses must assess their specific needs, weighing initial investments against long-term gains.

Not all businesses will benefit from the same solutions. A small manufacturer may find a simple automated conveyor sufficient. In contrast, a large facility may require an intricate network of robotics and IoT integration. It's important to reflect on your own operations and the potential for automation. Evaluate your goals and resources before deciding on the right fit. Always be open to refining your approach as technology evolves.

2026 Industrial Automation Solutions Evaluation

Assessing Compatibility with Existing Systems and Processes

When selecting industrial automation solutions, compatibility with existing systems is crucial. Evaluate current systems before making decisions. Understanding how new tools integrate is vital. A mismatch can lead to delays and increased costs. Your workforce may struggle with adapting to new technologies. This can create friction and inefficiencies.

Consider your hardware and software landscapes. All components need to communicate smoothly. Investigating the learning curve for employees is essential. Training might become necessary, adding extra time. It’s important to visualize how these changes affect daily operations. Sometimes, the best solutions aren't the flashiest ones. They should work seamlessly within your existing framework, not disrupt it.

Conduct thorough assessments of existing processes. Identify which areas need enhancement and how automation can help. A well-thought-out implementation plan reduces problems. However, be prepared for unexpected challenges. You might discover that certain systems need upgrades or replacements. Adapting is key to achieving long-term success in automation. This process requires thoughtful reflection and a willingness to address shortcomings.

Analyzing Cost vs. Benefit for Selected Automation Solutions

When selecting industrial automation solutions, understanding cost versus benefit is crucial. A report from McKinsey indicates that companies can expect to see a return on investment (ROI) of 20-30% within two years of implementing automation. However, many businesses overlook hidden costs. These include maintenance, training, and updates.

Implementing automation can lead to increased efficiency. For instance, research shows that automation can improve production speed by up to 50%. But, it requires a careful analysis. Not all automation systems deliver the same value. Companies must weigh the upfront costs against potential long-term savings.

A survey from Deloitte suggests that 54% of organizations struggle to measure the effectiveness of automation initiatives. These companies must ask critical questions. Is the solution scalable? Will it adapt to changing market demands? Rushing into automation can lead to unexpected pitfalls. Thoughtful consideration is essential for lasting success.

Related Posts

-

How to Implement Manufacturing Automation Effectively?

-

Top 5 Benefits of Using a Metal Engraving Machine in Your Business?

-

Top 10 Best CNC Engraving Techniques for Precision and Quality

-

Why You Should Consider a Wood Engraving Machine for Your Projects?

-

Top 10 Automation Solutions Tips to Boost Your Business Efficiency

Arsun Engineers is the well-known manufacturer, exporter, and supplier of highly operational machines.

Products

Automation

Get in Touch !

- 56/1 Vithalwadi GIDC, 364001 Bhavnagar, Gujarat, India

- +91 9426 816 961

- +91 7222 841 841

- sale@wallandmachinery.com