Top 10 Best CNC Engraving Techniques for Precision and Quality

CNC engraving is an art that combines technology with craftsmanship. It requires precise techniques to achieve high-quality results. According to John Miller, a leading expert in CNC engraving, "Every engraving project teaches us something new about precision." This highlights the ongoing learning process in the industry.

Developing the best techniques for CNC engraving can be challenging. It takes time and practice to master the skills. Often, engravers must confront unexpected issues. Mistakes can lead to wasted materials and frustration. Yet, each challenge can be a stepping stone toward improvement.

In this guide, we will explore ten key techniques that can enhance precision and quality in CNC engraving. These techniques can help both novices and experts alike. Embracing these methods can elevate your projects to new heights. Whether you are engraving intricate designs or simple patterns, precision is essential for success in CNC engraving.

Understanding CNC Engraving: Definition and Its Importance

CNC engraving is a crucial technique in the manufacturing world. It involves using computer-controlled machines to create precise designs on various materials. The importance of CNC engraving is evident in countless products we use daily. From decorative items to intricate parts in machinery, precision is key. A slight error can lead to significant flaws in the end product.

Understanding CNC engraving also helps us appreciate the skill involved. The machine's precision requires careful programming. Each engraving needs meticulous detail. There are instances where the outcome does not match expectations, requiring adjustments and reflections on design processes. For example, uneven depth or unintended patterns can occur. These challenges, though frustrating, drive improvement and innovation in techniques. It emphasizes the need for continuous learning and adaptation in this field. Each project teaches something new about the equipment and materials used.

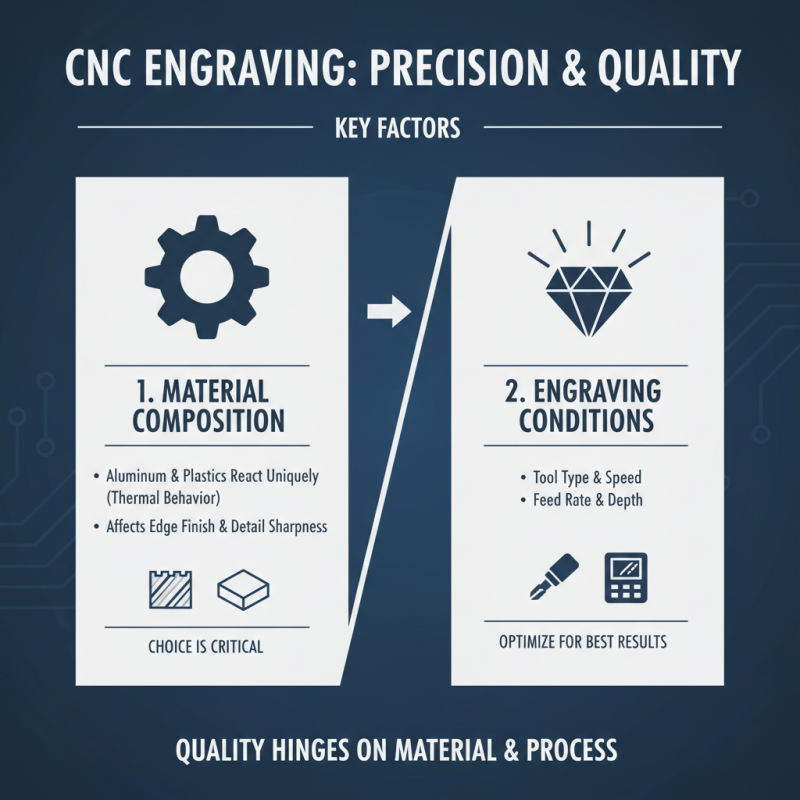

Key Factors Influencing CNC Engraving Precision and Quality

Precision and quality in CNC engraving hinge on several key factors. Material composition is critical. Different materials react uniquely to engraving conditions. A study revealed that aluminum and plastics exhibit distinct thermal behaviors during machining. This can affect edge finish and detail sharpness. Choosing the right material can greatly influence the final outcome.

Machine calibration is equally important. Regular calibrations ensure consistent performance. According to industry reports, a mere 0.1mm error in machine settings can lead to significant variations in engraving quality. This highlights the need for routine checks. Operators must remain vigilant about wear and tear on tools. Even high-quality tools can dull over time. A worn tool can compromise precision, leading to unexpected results.

Moreover, feed rate plays a significant role. Slower feed rates often yield smoother finishes, yet they may not be optimal for every project. Conversely, excessive speeds can produce rough edges and diminish detail. It's a delicate balance. Finally, environmental factors like temperature and humidity should not be overlooked. They can influence material behavior and machine performance. Neglecting these aspects may result in less than ideal quality. Engraving is an intricate process that requires constant attention and adjustment.

Top Techniques for CNC Engraving: An Overview of Methods

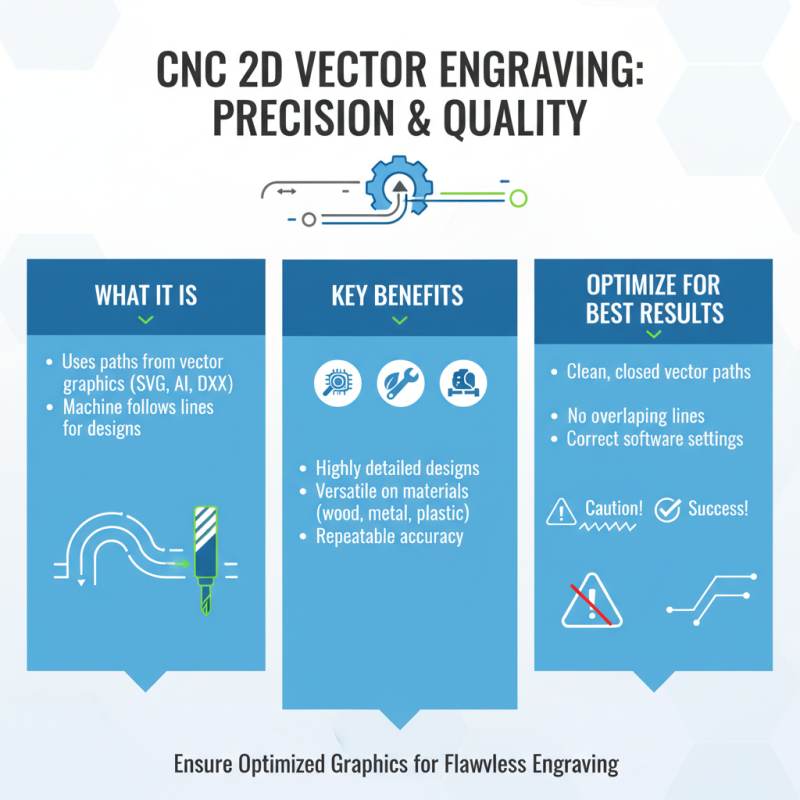

CNC engraving techniques play a crucial role in achieving precision and quality. Among the best methods, 2D vector engraving stands out. It uses paths defined by vector graphics. This technique allows for detailed designs on various surfaces. However, it can lead to inaccuracies if the vectors are not properly defined. Ensure your graphics are optimized to avoid common pitfalls.

Another effective method is 3D engraving. This creates depth and texture in designs. The results are visually stunning, but the setup can be tricky. Miscalculations in tool heights or feed rates may result in undesirable outcomes. It requires careful planning and testing to achieve the best results.

Laser engraving is also popular for its speed and versatility. It can handle diverse materials, from wood to metal. Precision is key, but handling different substrates can be challenging. Each material reacts differently under the laser. It’s essential to notice these differences for optimal results. Failing to adjust settings may lead to burns or incomplete engravings.

Comparative Analysis of CNC Engraving Materials and Their Uses

CNC engraving utilizes various materials, each offering unique benefits and challenges. Wood is popular for its versatility. It’s easy to carve, making it great for intricate designs. Reports indicate that nearly 40% of CNC engravings are done on wood. However, wood can splinter or warp, which affects precision.

Metals like aluminum and steel are ideal for durable products. They provide sharp details and longevity. However, metal engraving poses challenges. High-speed processes can lead to overheating, distorting the final product. A study showed that 25% of errors in metal engraving stem from improper cooling techniques.

Plastics are emerging materials in CNC engraving. They are lightweight and flexible. Yet, they can melt or chip during engraving. It suggests a fine balance when selecting speeds and feeds. Understanding these material properties significantly impacts quality outcomes in CNC work.

Future Trends in CNC Engraving Techniques and Technologies

The future of CNC engraving is shifting rapidly. A recent industry report predicts that the global CNC engraving machine market will grow at a CAGR of 6.8% from 2021 to 2028. This growth indicates a strong interest in advanced technologies for enhanced precision. New methods, such as laser and waterjet engraving, allow for intricate designs. However, the need for skilled operators is crucial. Many companies face challenges in training workers effectively.

Innovations in software are also shaping this field. Integrating AI and machine learning can improve machining efficiency. These technologies analyze patterns and predict potential faults. Yet, there is a concern about reliance on automation. Over-dependence on software may lead to skill degradation among operators. Additionally, while CNC machines become smarter, maintaining a human touch remains vital for quality assurance.

Sustainability is another emerging trend in CNC engraving. As companies strive for eco-friendliness, biodegradable materials are gaining traction. However, adapting existing machines to handle new materials poses challenges. The industry must balance technological advancements with sustainable practices. This way, the future of CNC engraving can meet both precision and environmental standards.

Top 10 Best CNC Engraving Techniques for Precision and Quality

| Technique | Material Compatibility | Precision Level | Quality of Finish | Future Trend |

|---|---|---|---|---|

| Laser Engraving | Wood, Acrylic, Metal | High | Excellent | Automation and AI |

| Diamond Drag Engraving | Glass, Metal | Medium | Good | Sustainability practices |

| Rotary Engraving | Wood, Soft Metals | High | Decent | Enhanced Tooling |

| Water Jet Engraving | Metal, Stone | Very High | Excellent | Advanced Material Research |

| Plasma Engraving | Metal | High | Moderate | Integration with IoT |

| CNC Milling | Various Metals, Plastics | Very High | High | Smart Manufacturing |

| Chemical Engraving | Metals | Medium | Good | Regulatory Compliance |

| Bead Blasting | Metal, Plastic | Low | Fair | Surface Treatment Innovations |

| Etching | Metal, Glass | Medium | Good | Digital Process Automation |

| Sublimation | Polymer, Coated Metal | High | Excellent | Customization Trends |

Arsun Engineers is the well-known manufacturer, exporter, and supplier of highly operational machines.

Products

Automation

Get in Touch !

- 56/1 Vithalwadi GIDC, 364001 Bhavnagar, Gujarat, India

- +91 9426 816 961

- +91 7222 841 841

- sale@wallandmachinery.com